Amee Engineers is one of leading manufacturer of Air Heater which offers variety of Air Heater to solve customer’s specific application and its need. Different kind of Air Heaters we manufacture are Tubular type, Ceramic Strip type, Bobbin and Ceramic base with open heating coil type.

Air Heaters works on Thermal law of Convection. So to enhance its efficiency we suggest fins on the heaters. That gives increased surface area and it indirectly increases convection area of heating element. That ultimately improves the heat transfer rate from heater to air medium. To improve the performance of the heater we rely on some characteristics such as its manufacturing process, selection and quality of raw material & technically efficient staff.

So, we, Amee Engineers is here to help you as we have expertise in thermal designing along with that have the finest and state of the art- in-house manufacturing and testing facility. Our custom design fins and superior quality of raw material enhance its efficiency.We also offer custom design Heater banks for duct heater on client’s specification. Our Air Heaters are proven and appreciated by the clients because of its consistency and reliable life span by maintaining regular supplier list of the numbers of OEM’s.

Types of Air Heaters

- Tubular

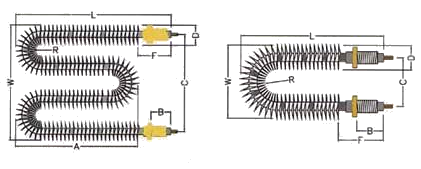

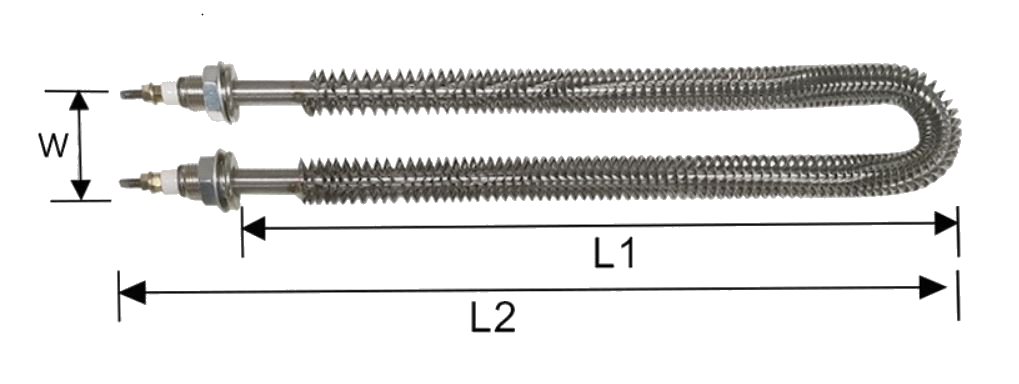

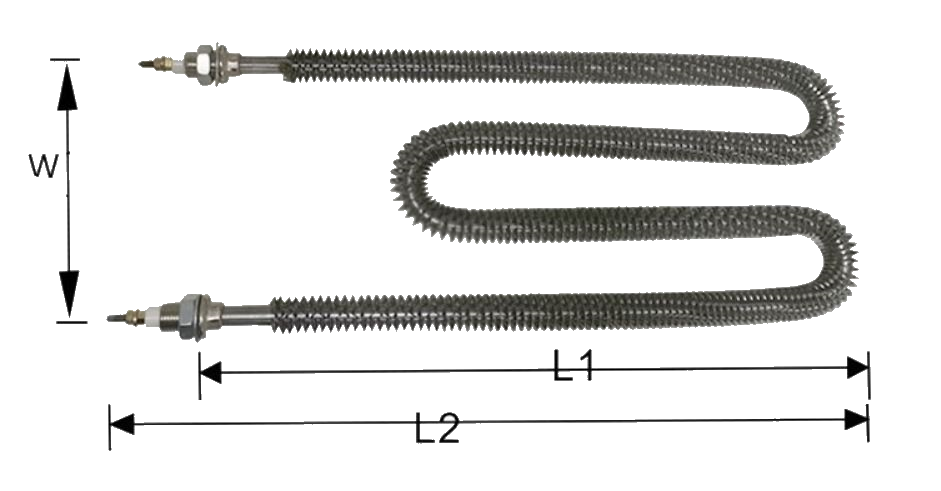

- With Fins(Sample Image of M type and U type)

- Without Fins

- Material of Heater tube: SS304 / SS316 / Inconel

- Material of Fins: GI / SS304 / SS316

- Material of Clamp (U type Heaters): GI

- Fittings (Optional): Brass / SS

- Terminal covers: Flame proof /Dust proof/open type

- Ceramic Strip Heaters

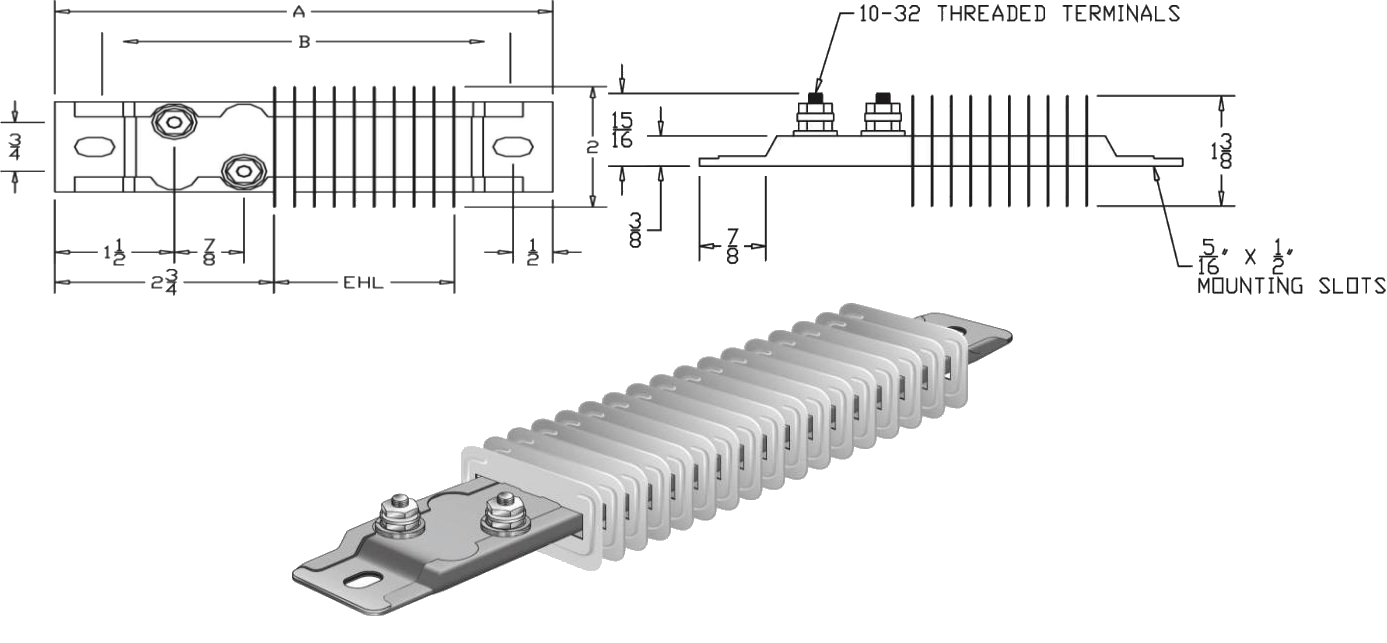

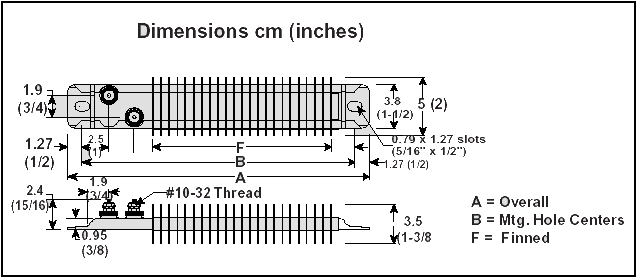

- Fins type(Sample Image of Strip type fins heater)

- Without Fins type

- Material of Heater: GI / SS202 / SS304 / SS316

- Material of Fins: GI / SS202 / SS304 / SS316

- Ceramic Bobbin type

- 6 Groove and 8 Groove type

- Variety of Diameters and Length

- Ceramic Base with Open Heating Coil

- Some type use for the backing/preheating oven

- Range of our Air heaters

- Heating capacity of Heater: 0.3 KW-6 KW

- Heating capacity of Heater Bank: 3 KW to 45 KW

- Temperature Range: 70°C – 650°C

| Heating Surface Material | ||||

|---|---|---|---|---|

| SS-304 | SS-310 | SS-316 | Incoloy 600 | Inconel 800 |

- Oven

- Dryer

- HVAC

- Moisture separator

- Pharma Industries

- Chemical processing industry

- Food processing industry

- Cement industry

- Type of Heater :Tubular / Strip / Bobbin /Open coil

- Diameter

- Tubular Heater: ɸ 8 mm / ɸ 10 mm / ɸ 11 mm / ɸ 16 mm

- Bobbin type: 24 mm to 56 mm

- Length

- Bobbin type: 200 mm to 2000 mm

- Tubular Heater: 250 mm to 3500 mm

- Shape of Heater: U / M / Multiple Loop / Single Loop / Straight type

- Bending radius for customised shapes

- Material of Heater: GI/ SS304/ SS316

- Material of Fins: GI/SS304/SS316)

- Density of Fins: Fins per Inches (FPI)

- Density of Heat in terms of Watts

- Supply Voltages: (Single Phase/Three Phase Star/Three Phase Delta)

- Length Differentiate: Hot Zone(Heating surface) + Cold Zone (non heating surface)

- Fitting/Clamp: GI / SS / Brass

- Terminal Type : Brass / SS / Cable (teflone/fiberglass/silicon insulated)

- Terminal Cover: Flame proof (FLP) /Dust proof (IP65) / Open type

- Working Temperature

Send us an inquiry