Immersion Heater is one of the Tubular type of Heater inserted in flange with leak proof brazing or TIG welding. They are used to heat many liquid substances like oil, water, chemicals. Our Heater is made in such a way that it can withstand and perform in challenging environmental conditions. Even some times High Density Cartridge Heater is used in place of Tubular type of Heaters. Immersion Heater works on the thermal law of convection, so it must have proper watts Density so it will not get puncture or blast during the process.

We AMEE ENGINEERS have almost all required production facility and testing appratus under the one roof, so we can deliver our quality products ontime to our esteem customers. Our Immersion Heaters are appreciated by the customers. The Heater’s performance is tested under challenging circumstances so to have a longer life span. It all comes from our vision and workmanship to deliver superior quality of products in the market. Over the period of time and experience we have achieved expertise in manufacturing and developed extensive range of Immersion Heaters which have been listed in specifications.

- Variety of Shapes/Geometry of Heaters: U / Single Loop / Multiple Loop / Any customize structure/design we are able to make

- Available Diameters: ɸ 8 mm / ɸ 10 mm / ɸ 11 mm / ɸ 16 mm

- Length Range of Immersion: 200 mm –2000 mm

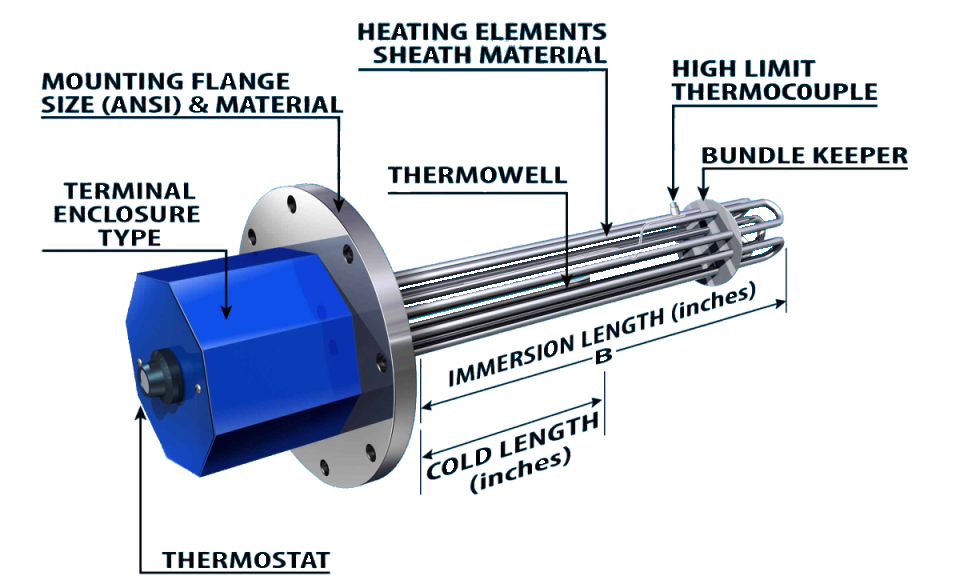

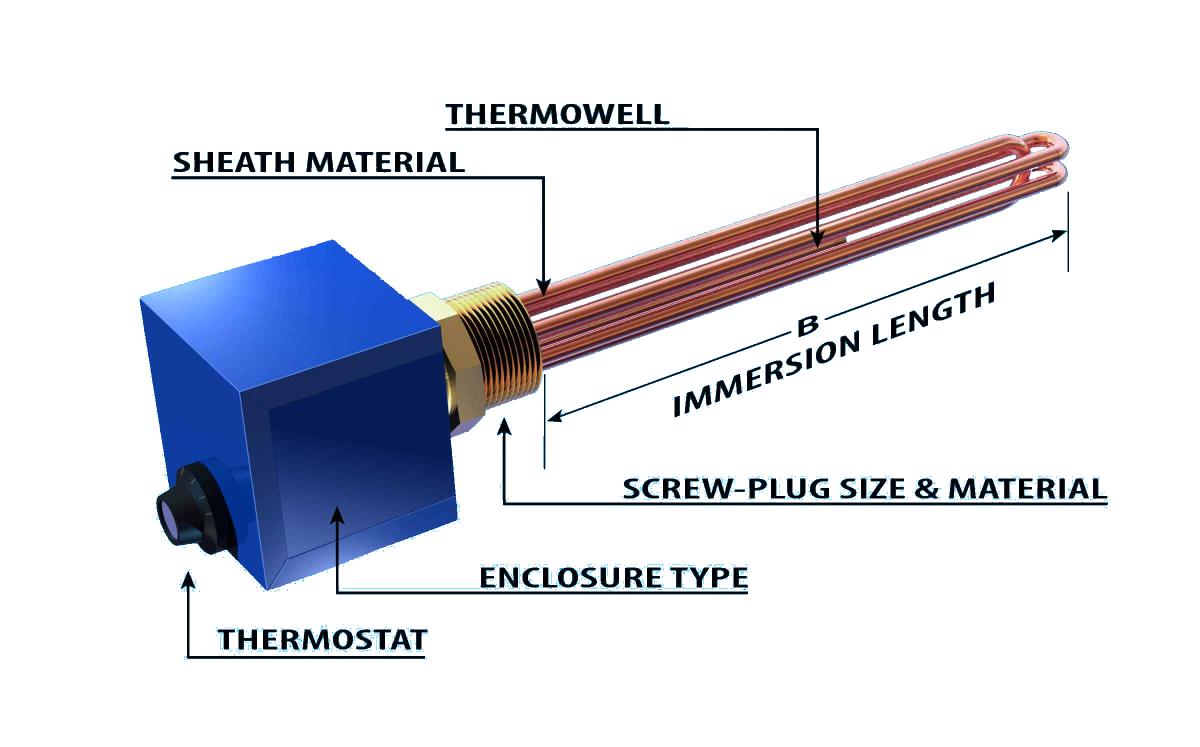

- Outer Sheath material: SS304/SS316/Copper/Inconel

- Flange Type: Flat Plate type/ Round type/BSP fittings

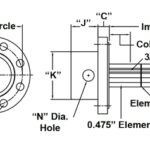

- Arrangement of Heater in Flange: PCD (Pitch circle Diameter)/ Pitch of Heaters

- Flange mountings: Threaded/Bolt mounted (Simple Holes in periphery)

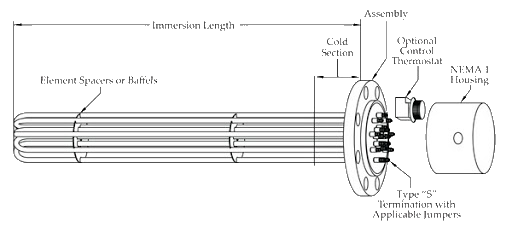

- Terminal Enclosures: Flame Proof (FLP)/Dust Proof (IP65)/ Simple backlit or metal cover

- We also offers optional feature of Inbuilt thermocouple/temperature sensor

| Heating Surface Material | ||||||

|---|---|---|---|---|---|---|

| SS-304 | SS 310 | SS-316 | Incoloy 800 | Inconel 600 | Copper | Titanium |

- Thermic Fluid Heating

- Water Heating

- Oil Heating

- Plating Bath Heating

- Alkaline cleaning solutions, Tars, Asphalt

- Food Processing Equipment

- Heat Exchangers

- Boiler

- Chemical Industry

- Watts & Supply Voltages (24V DC / 110 V / Single Phase / Three Phase Star / Three Phase Delta)

- Heating Material (SS304 /SS310 / SS310 /Copper/ Inconel 600 / Inconnel 800)

- Heater Geometry/Structure/Design: U / Single Loop / Multiple Loop / Any customise geometry need Detail Drawing

- Diameter of Heater Tube

- Number of heating coils in flange

- Total length of Heater

- Hot zone(Immersion Length) & cold zone(Non Immerse Length)

- Terminal Thread Size: M4 Thread / M6 thread

- Flange type

- Flat Plate type

- Round type

- BSP Brass Flange (1/2” BSP/1” BSP/1.25” BSP /1.5” BSP / 2” BSP / 2.5” BSP)

- Special case Metric threaded Fittings available

- Arrangement of Heater in Flange

- PCD (Pitch circle Diameter for Round type flange)

- Pitch of Heaters (Flate Plate type)

- Terminal Covers

- Flame Proof (FLP)

- Dust Proof (IP65)

- AMEE’s Standard backlight or Metal guard

- Thermowell (optional feature)

- Diameter

- Length

- Position in Flange

- Thermocouple (optional feature)

- Bimetallic type

- Thermocouple: J Type/K type/RTD pt 100

Send us an inquiry